New 2D Codes for Marking and Coding of Flatpacks for Furniture Industry, Logistics & Retail

We support furniture manufacturers and furniture producers in the transition from 1D to 2D codes - with Marking and Coding Technology from REA JET and Code Verification Systems from REA VERIFIER

Request a quote directly now! You will receive a quote from one of our marking or code experts within two working days.

Move to 2D codes now!

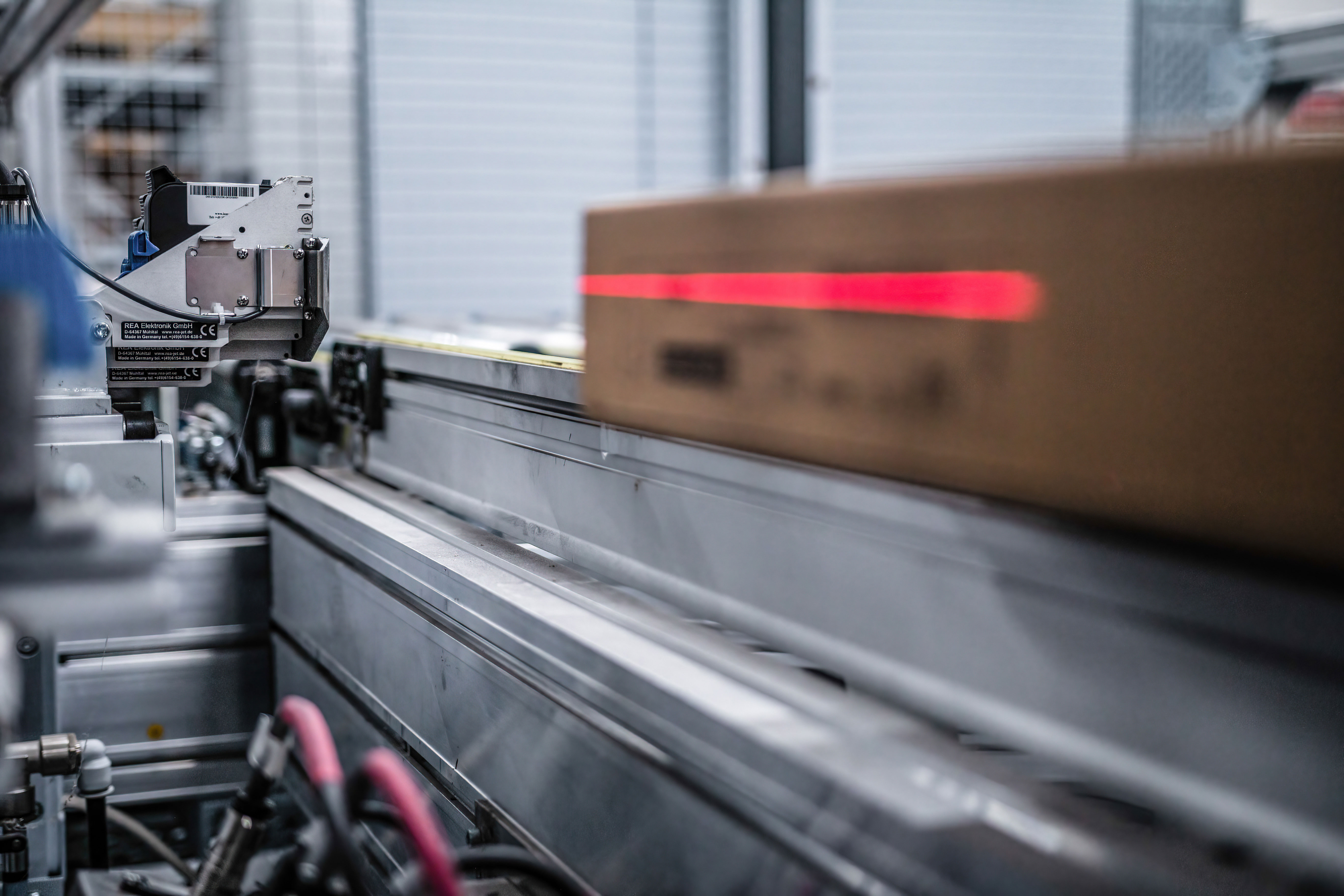

High resolution printing of 2D codes on flatpack or ready-to-assemble furniture packaging: REA JET Verify 2D codes to the required quality according to ISO/IEC 15415: REA VERIFIER

- At many of the world's largest furniture companies, flat-packs, furniture packaging and labels have to use 2D codes as early as 2023, in addition to the existing 1D code

- Modernization of packaging and product identification by 2D Data Matrix codes (DMC)

- Easy provision of comprehensive product information for retailers and logistics

- Using the GS1 Digital Link as a new standardized solution for digital product identifcation

- Print Data Matrix symbols with GS1 Digital Link on flat packs and furniture packaging and verify afterwards

Printing 2D codes

With the REA JET HR in the required 1.5 C quality according to ISO/IEC 15415

The REA JET HR high resolution marking and coding system complies with ISO/IEC standard 15419 and meets all printing requirements of the furniture industry. That is why it is the first choice for global furnishing groups, furniture manufacturers and furniture producers - extensively tested, proven and successfully in use worldwide.

The printing technology of the REA JET HR Inkjet Printer fully complies with the requirements for printing Data Matrix Codes (DMC) specified in ISO/IEC 16022. In combination with the pollutant-free REA JET Pigmented Black NC Chip ink, the high resolution printing system offers the following advantages for marking flat packs and furniture packaging:

- Excellent print contrast and contour sharpness on cardboard boxes or labels

- Compliance with the required code quality according to ISO/IEC 15415 (min. 1.5 C) even on brown cardboard and cartons

Our high resolution REA JET HR inkjet printer based on HP cartridges is ideal for use in the furniture industry. Below are the key benefits that make our printing system a must-have in the furniture industry:

- Worldwide proven printing technology

- Maintenance-free system - new print unit with each cartridge change on the fly

- Print resolution up to 600 dpi, for optimal print quality

- High availability - 24/7

- Alphanumeric texts and logos

- 1D (barcodes) and 2D codes (DataMatrix codes with GS1 Digital Link, rectangular or square)

- Label replacement through direct printing = cost and resource savings

- Clean, environmentally friendly, solvent-free and no pollution of the production environment

Verify 1D and 2D codes

ISO/IEC 15415 compliant and guarantee high first-pass reading rates

Well-known multinational furniture companies have already chosen the REA VeriCube for quality inspection of their printed codes. The REA VeriCube is an industry-proven, state-of-the-art DataMatrix and barcode verifier.

With the demands of the retail industry changing from 1D to 2D codes, the VeriCube code verification system is ideally suited for code quality inspection. It verifies in accordance with all relevant GS1 specifications in the furniture industry - ISO/IEC 15415, ISO/IEC 15416, ISO/IEC 29158 (DPM), ISO/IEC 15426-1, ISO/IEC 15426-2 as well as ISO/IEC 16022. The result is output in an overall score. Many applications require a minimum grading of 1.5 C according to ISO/IEC 15415.

The advantages of the REA VeriCube:

- Proven code verifying equioment for 1D and 2D Codes, the reference system of its class

- Stationary at the workstation or integrated in machines or systems

- Contact-free code verification with CMOS camera system Measurement of directly marked codes - Direct Part Mark (DPM)

- Application in three measuring positions: lateral, standing upwards, standing downwards for best possible inspection accuracy

The HR printing system and the VeriCube code verification system form a perfectly cooperating system solution from REA - Made in Germany. High first-pass reading rates at scanner checkouts at the point of sale and in internal logistics processes are thus guaranteed.

Your advantages with REA

The difference to our competitors

Quick response

Direct contact

Many years of experience

Fill out the contact form on the right and you will receive feedback from our marking und coding specialists within the next two work days hours. If you have any questions about marking und coding, we will be glad to help you, please call us directly.

You are also welcome to arrange a virtual appointment via video telephony.

Many thanks for your inquiry!

Your request will be processed as soon as possible.

In order to be able to help you even better,

please answer the following questions:

Thank you very much for your visit at REA!

Thank you for your interest in our products.

You can find further impressions on our website.